Our Solution

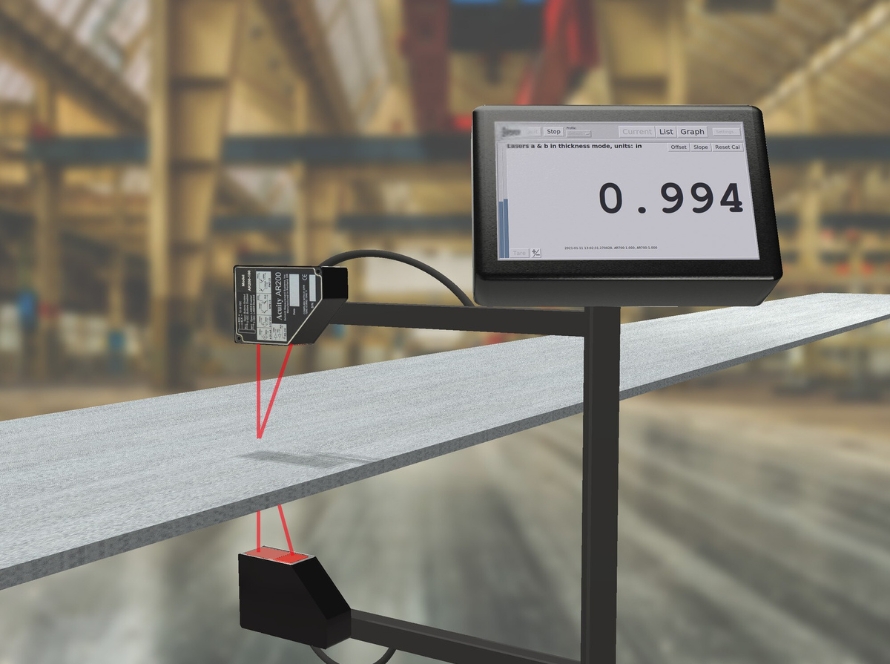

Thickness Measurement System

At Radicon, our Thickness Measurement Systems are designed to provide precise, non-contact measurement of material thickness in real-time. These systems help industries maintain product quality, ensure compliance with specifications, and optimize production processes by detecting deviations early.

Key Features

- High-precision, non-contact thickness measurement

- Real-time monitoring for continuous production lines

- Compatible with various materials: metal, plastic, glass, and composites

- Advanced sensor technology for consistent accuracy

- Easy integration with PLC and SCADA systems

- Data logging and trend analysis for quality control

- Customizable settings for different production requirements

Applications

- Metal sheets, plates, and strips measurement

- Plastic films and packaging materials

- Glass production and quality control

- Automotive and aerospace components

- Industrial manufacturing lines requiring high-precision monitoring

Benefits

- Ensure consistent product quality and compliance

- Reduce material wastage and production defects

- Improve efficiency with real-time process monitoring

- Support predictive maintenance and process optimization

- Generate accurate records for reporting and analytics

With Radicon Thickness Measurement Systems, manufacturers can achieve reliable, precise, and efficient quality control. Our solutions are robust, adaptable, and built to meet the demanding standards of modern production environments.