Our Solution

Vibration Monitoring System

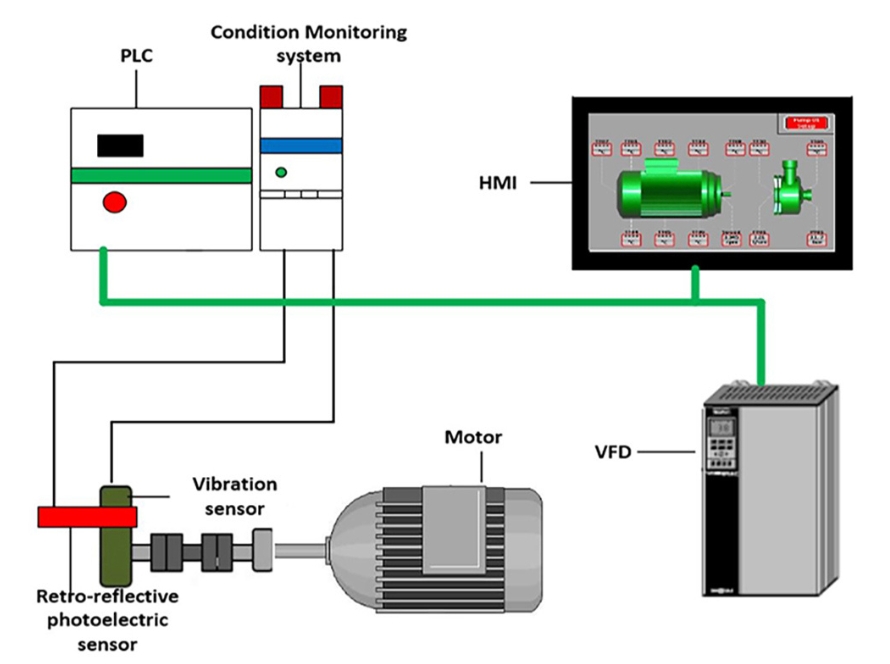

At Radicon, our Vibration Monitoring Systems are designed to provide accurate, real-time monitoring of machinery and equipment to ensure optimal performance and prevent unexpected failures. These systems use advanced sensors and analytics to detect abnormal vibrations, identify potential faults, and help industries implement predictive maintenance strategies.

Key Features

- Real-time vibration measurement and monitoring

- Advanced signal processing for fault detection

- Non-intrusive installation with minimal downtime

- Continuous condition monitoring for rotating machinery

- Customizable alarm thresholds and notifications

- Data logging and historical trend analysis

- Integration with existing SCADA and PLC systems

Applications

- Rotating equipment: motors, pumps, compressors, and turbines

- Industrial manufacturing plants

- Power generation and transmission systems

- Automotive and heavy machinery maintenance

- Predictive maintenance programs in multiple industries

Benefits

- Prevent costly equipment failures and unplanned downtime

- Increase equipment lifespan through early fault detection

- Enhance operational efficiency and reliability

- Reduce maintenance costs with condition-based interventions

- Provide actionable insights for process optimization

With Radicon Vibration Monitoring Systems, industries can maintain high reliability and operational efficiency. Our solutions are adaptable, precise, and engineered to meet the demanding requirements of modern industrial environments.